Piles represent one of the oldest methods of deep foundation of constructions of various types and the most widely used method of present times. That is why this technology adopts one of the most important places within the range of technologies supplied by the Zakládání staveb, Co. The total amount of around 100 types of piles can generally be divided into two groups, depending on whether it is necessary to remove soil from the space occupied by the pile in the course of its production (replacement piles), or whether this soil is, by various means, pushed aside to the surroundings of the future pile (displacement piles). Piles most commonly carried out in the Czech Republic are bored piles, which stand for the main and typical example of the first group of piles mentioned above, making more than 90 % of all piles on our market. This is due to their rather widest universal character required with respect to the varied geotechnical conditions at construction sites in our country, as well as by certain tradition and experience with large-diameter boring. According to the ČSN EN 1536 Standard bored piles include circular components of 300-3000 mm in diameter without length limits, as well as non-circular components, so called soldier piles (diaphragm wall panels), if these are cast at one advance and their cross-sectional area is less than 10 m³. Bored piles are designed mainly as deep foundations able to transmit concentrated axial loads (especially compressive), but also lateral loads.

Due to their big carrying capacity given by the suitable choice of diameter and clamping into the bearing subsoil, they are very often designed as isolated ones, directly forming column foundations of halls and bridges.

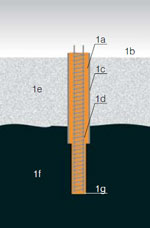

Bored pile scheme

Bored pile scheme

1a) pile head

1b) working platform

1c) casing

1d) reinforcement (reinforcement cage)

1e) soft soil

1f) bearing foundation soil

1g) pile footing

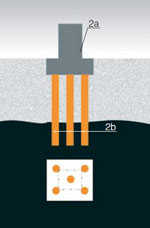

A group of piles scheme

A group of piles scheme

2a) connecting structure (footing)

2b) piles in group

Their heads can be furnished with monolithic bored footings with calices for direct assembly of pre-fabricated reinforced concrete columns or with connecting reinforcement for the attachment of monolithic columns. The piles can also be used without any problems as isolated foundations for steel columns. In cases of extremely heavy loads the piles are designed in groups connected through a head by a reinforced concrete footing, strip footing or a slab.

Holes for piles are usually carried out with the technology of rotary-grabbing drilling with the use of special tools, especially drilling buckets, spirals and crowns, rarely also with grabbing sinking. In unstable soils the holes are cased to ensure stability of their walls and bottom during the process of pile installation. When piles of a diameter less than 1500 mm are cased, steel connectable casings are mainly used. They are installed either directly using a special equipment on the drilling set with so called casing equipment used both for installation and for pulling out casings. Slurry casing is presently used only for casing holes of large diameter. After finishing and cleaning a hole it is normal to put in a reinforcement cage; further the pile casting follows. In case of dry holes it is carried out with concreting pipe with a skip directing the concrete flow into the hole so that it did not segregate. Water-bearing holes or holes cast with slurry are concreted through the so-called Contractor method with the use of water proof, releasable tremie pipes. Concretes of C16/20 to C30/37 types with a high degree of workability necessary for perfect pile concreting are used.

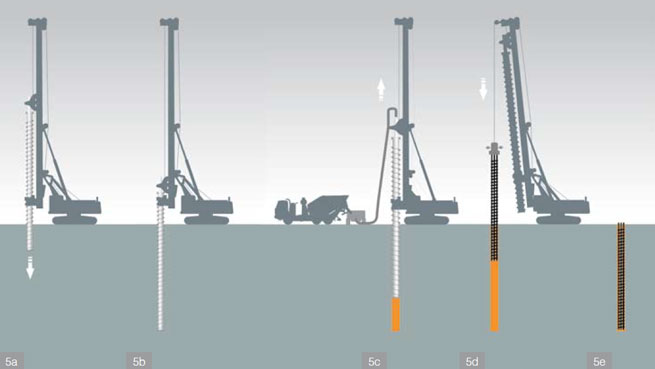

Technological process of carrying out bored piles cased with steel casing

3a) starting drilling works, installing the casing into a hole

3b) finishing boring of non-cased part of the hole under the casing

3c) inserting the reinforcement cage into the cleaned and cased hole

3d) pile concreting

3e) pulling the casing out of the concreted hole

Examples of soldier piles

4a) hydraulic grab

4b) rectangular panel

4c) T-shape panel

4d) H-shape panel

Piles carried out with a continuous flight auger (CFA), whose threads are welded on the central pipe with a bottom closure, represent a special type of bored piles. The auger is drilled into the soil without excavating, i. e. that even in unstable soils the hole is constantly cased with soil, which sticks to the auger threads. After reaching the projected depth the concreting starts through the central pipe of the continuous auger. A pump directly connected with a flexible hose to a drilling machine head is used here.

In the course of concreting the permanently rotating auger is continuously pulled out of the hole at a speed corresponding with the volume of concrete pressed into the emptied hole. This procedure is operated by a microprocessor in the way that there was no space left in the foundation soil without being subsequently filled in with concrete. After the concreting is finished up to the level of a working platform and the fallen off soil from the auger is removed, the fresh pile concrete can be furnished with a reinforcement cage, which is continuously pressed into the concrete, however not vibrated, in order to prevent segregation of highly plastic and well workable concrete. CFA piles are rather suitable in appropriate geotechnical conditions, because the productivity of work in the course of their production reaches almost several multiples of working productivity achieved in production of other types of piles.

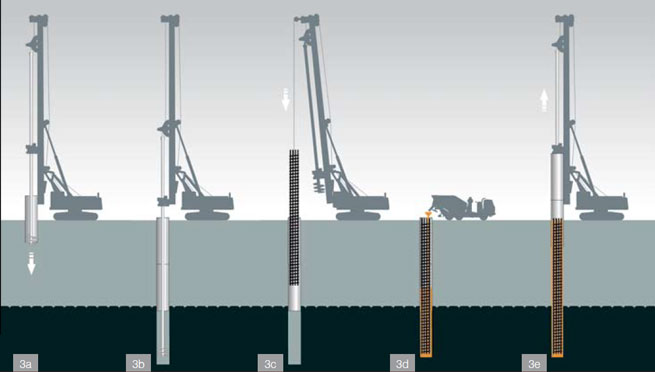

Technological process of carrying out piles with a continuous flight auger (CFA)

5a) starting drilling works

5b) finishing boring in the projected depth

5c) pile concreting and concurrent pulling out the continuous auger

5d) installing a reinforcement cage into the freshly concreted pile

5e) finished pile