Deep compaction of soils

This technology is applied for deep compaction of grainy non-cohesive soil with the use of a vibrating tool that infers horizontal vibrations to the surrounding soil in the process of compacting. The penetration of a vibrating tool into the soil is assisted by flush water or flush air led to its spike. A deep vibrating tool can be driven by an electric or hydraulic power source and it is normally hung up on a crane carrier or set firmly to a drilling set lafette - in this case its penetration is simultaneously supported by down pressure. Compaction of soil decreases its porosity until relative compactness of ID = 0,7 to 0,8 is reached.

This technology is also suitable for compacting of non-cohesive soils, landfills, high ground bodies and their subsoils. Vibroflotation can also be used for decreasing permeability of non-cohesive soils, by one to two grades. The effectiveness of compaction is documented by results of static or dynamic penetration, or possibly by a loading plate test.

Deep compaction of soils

Deep compaction of soils

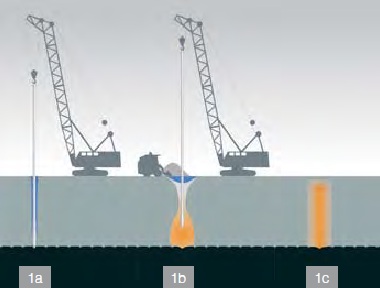

1a) penetration of a vibrating tool into the soil, the tool is penetrated

into the soil with the help of horizontal vibrating effect, flush and its own weight

1b) deep compaction with filling of additional material

to the puncture mouth

1c) compacted column of soil

Gravel columns

Gravel columns carried out with the method of vibroflotation represent elements realised mainly in cohesive soils with a deep vibrating tool (the same as with deep compaction). A hole created with a vibrating tool is gradually filled in with gravel, which is compacted through a vibration method creating a pier of irregular circular cross section. Identically with the deep compaction process, the penetration of the vibrating tool into the soil is assisted by flush water or air, penetration can be simultaneously supported by down pressure, if the vibrating tool is firmly set to a carrying set lafette.

When additional gravel is filled into the puncture mouth, the vibrating tool is usually loosely hung on a crane carrier, in case of filling to the spike the tool is set to the carrying set lafette. Gravel columns improve qualities of foundation soils, especially by increasing their shearing strength, improving their deformation qualities and accelerating their consolidation. Their usage in a form of independent foundation components is, however, limited and it is bound to proving the bearing capacity of a pier under the given geological conditions. Under normal conditions the method of vibroflotation is used for realisation of gravel columns of approx. 700 mm in diameter.

Gravel columns can be preferably used for improving the bearing capacity of shop floor subsoils, storage buildings, ground bodies, as well as smaller construction buildings, as for example family houses.

Carrying out of gravel columns with gravel

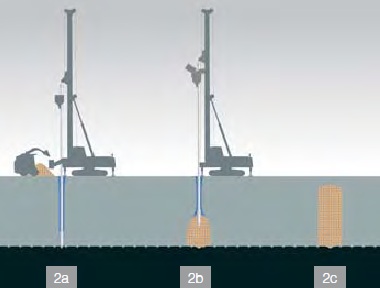

filling to the tool spike

2a) Penetration of a vibrating tool into the soil;

the tool is penetrated into the soil with a help of horizontal

vibrating effect, flush and down pressure

of carrying machine

2b) carrying out of a gravel column

2c) finished gravel column

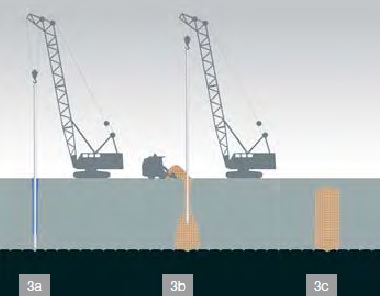

Realisation of gravel columns with gravel filling

to the puncture mouth

3a) penetration of a vibrating needle into the soil; the needle

is penetrated into the soil with the help of horizontal

vibrating effect, flush and its own weight

3b) realisation of a gravel column

3c) finished gravel column

Ground plan scheme of a deep soil compaction field.

Individual punctures of deep compaction are designed

in the vertexes of an isosceles triangle.