_sm.jpg)

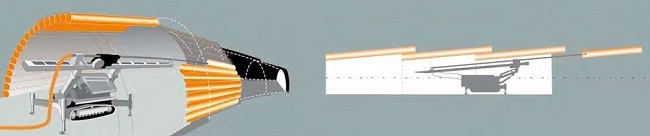

Jet grouting is a modern, fast and effective method of creating special foundation elements in soils and possibly in semi-solid rocks. The technology is based on grouting from a hole into surrounding soil carried out under high pressure of 30-55 MPa and with the use of cement and clay-cement mixtures.

A jet of grout mixture flowing through nozzles disaggregates a rock into separate chippings or individual grains, while they are mixed together and after their hardening they create desired elements (column, panel or their combination) and improve the qualities of grouted ground.

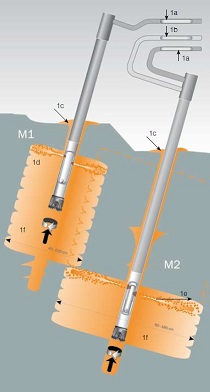

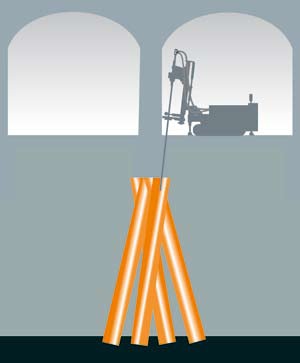

After a hole is drilled to a projected depth, cement mixture is pumped underhigh pressure into nozzles above the drilling tool. A jet of cement mixture goes through a nozzle and cuts and mixes the soil to the distance of 40-140 cm, if the method M1 (monophase) is used. With the M2 method (double-phase air) the jet of cement mixture is additionally rectified by a coaxial stream of compressed air to the distance of 120-220 cm. If the grouting string of rods is turning a foundation element- a column - is created. This is the most common use of this technology. If the grouting string of rods is not turning in the process of pulling out, a plane underground element is created, either as a segment or a wall. Strengths of created elements range between 0,5 to 15 MPa depending on the soil type, permeability coefficient lies within the scope of k = 10−8to 10−9 m.s−1.

tryska_sm.jpg)

_sm.jpg)

The principle of jet grouting technology with the use of methods M1 and M2

1a) grout mixture

1b) compressed air

1c) washed-up material

1d) a jet of grout mixture

1e) a jet of grout mixture and compressed air

1f) grouted column of soil

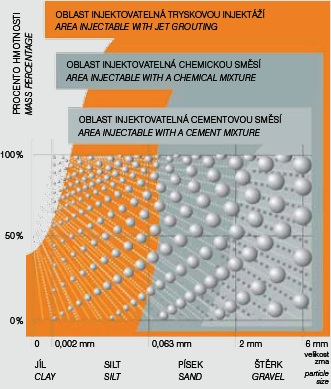

Area of applicability of jet grouting in individual soils

compared with standard and chemical grouting

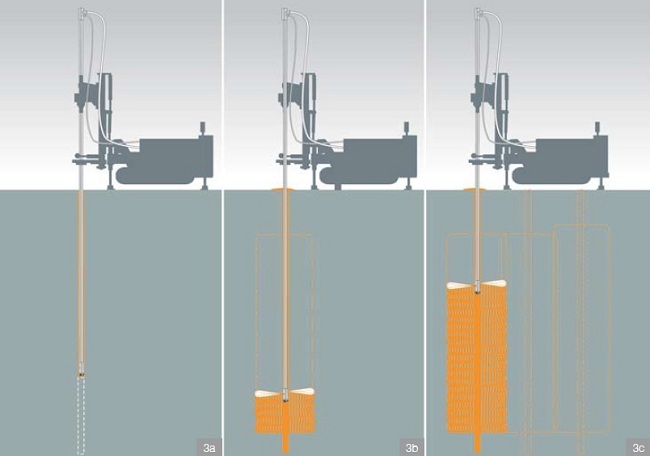

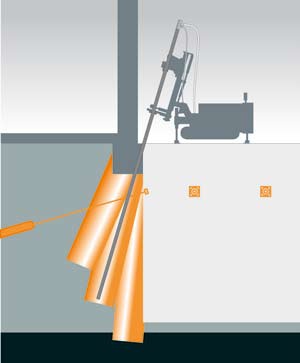

3a) Realisation of a medium-profile hole for jet grouting

A drilling set drills a hole to the bottom of a prospective jet grouted column. The drilling and grouting string of rods is equipped with a drilling tool anda monitor.

3b) Realisation of a jet grouted column

The transition from the drilling mode to grouting is done by redirecting grout mixture from the wash-up mode to the grouting one by inserting a steel ball into the drilling set. The ball closes the intake to wash-up openings and the mixture starts flowing into a nozzle-equipped monitor. The drilling set is equipped with a cycling and monitoring system that maintains and controls parameters of adjusted grouting pressure of mixture if the M1 method(monophase) is used, and parameters of air pressure if the M2 method (double-phase air) is used, grout mixture batching, rotation speed and gradual pulling out of the monitor.

3c) Finishing of a jet grouted column

Machine-controlled process of high-pressure grouting is stopped after reaching the upper projected level of grouting. The drilling set is further repositioned to a new hole and the described technological procedure is repeated.

| Underpinning of foundations of an existing building with jet grouting columns | Sheeting of a foundation pit with a jet grouted anchored wall and concurrent securing of the neighbouring building |

|  |

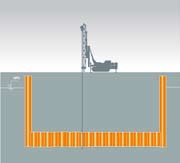

| Securing an underground work driving with a compact envelope made of jet grouting columns under the groundwater level | Creating a sealing screen from jet grouting columns |

|  |

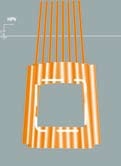

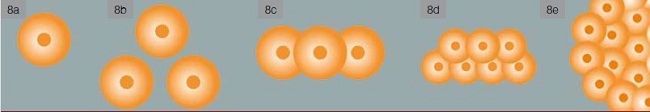

Alternative use of jet grouting columns

8a) jet grouting column

8a) field of jet grouting columns

8c) jet grouting wall

8d) doubled jet grouting wall

8e) jet grouting slab

olektory__sm.jpg) Because of the specific qualities of jet grouting, it is used in a wide range of rocks (from soft slushy and fine-grained soils to gravels). It can be rather suitable for underpinning foundations (a change of load as a consequence of building reconstruction, cuts close to foundations)for building impermeable walls preventing spreading of pollution (see Chapter Environment - Soil and Water Protection,Diaphragm walls), for creating envelopes of driven underground works, for casing walls of foundation pits in confined spaces, for sheeting of shafts, for breaking shear surfaces of slides, for consolidation of compressed soils, for carrying out anchor roots in complex geological conditions and for final sealing of sheeting constructions of other systems.

Because of the specific qualities of jet grouting, it is used in a wide range of rocks (from soft slushy and fine-grained soils to gravels). It can be rather suitable for underpinning foundations (a change of load as a consequence of building reconstruction, cuts close to foundations)for building impermeable walls preventing spreading of pollution (see Chapter Environment - Soil and Water Protection,Diaphragm walls), for creating envelopes of driven underground works, for casing walls of foundation pits in confined spaces, for sheeting of shafts, for breaking shear surfaces of slides, for consolidation of compressed soils, for carrying out anchor roots in complex geological conditions and for final sealing of sheeting constructions of other systems.

Creating an envelope from individual jet grouting columns for securing the subsequent over break of a tunnel gallery. The securing of tunnel callots and subsequent driving of the gallery is carried out step by step.