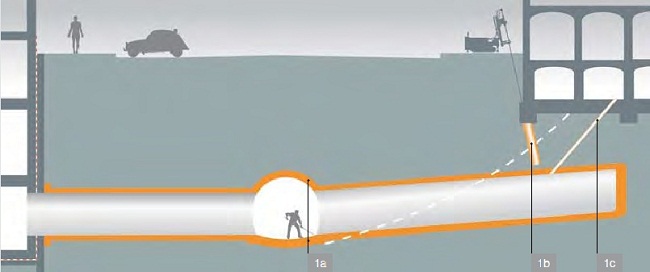

Using the technologies of special foundation for the realisation of a complex mining work - driven service collectors. The picture depicts securing driving of the main collector tunnel gallery and driven service lines with jet-grouting (1a), underpinning of the existing structure in the area of subsidence with jet-grouting (1b) and connecting holes for individual underground services (1c).

Substructures represent highly specialised engineering work sand their construction applies, to a large extent, works of special foundation engineering. These are mainly road and railway tunnels, driven collectors for service lines, driven sewage and water systems feeders and driven sewers and sewer connections. Technologies of special foundation offered by the Zakládání staveb, Co.,, and applied for the construction of these works are mentioned here in after:

Substructures represent highly specialised engineering work sand their construction applies, to a large extent, works of special foundation engineering. These are mainly road and railway tunnels, driven collectors for service lines, driven sewage and water systems feeders and driven sewers and sewer connections. Technologies of special foundation offered by the Zakládání staveb, Co.,, and applied for the construction of these works are mentioned here in after:

Sanitation (hardening) groutings

These sanitation works are carried out through standard grouting or jet-grouting, either upward or inclined. When standard grouting is used, overburdens, side walls and subsoils of a driven work are hardened with grout mixture; in the environment of non-cohesive soils this grout mixture is injected through tube-a-manchette pipes or, in semi-rock and rock environment, with the help of medium-profile holes. This hardening enables follow-up realisation of safe driving of a mining work. The grouting is commonly arranged geometrically into fans, each of them consisting of several holes. The grouting is carried out level by level, usually in an upward way. Grout mixtures commonly used for grouting include cement, clay-cement or chemical ones. Both drilling and grouting works are carried out step-by-step from driven galleries and always ensure subsequent step of drilling; or they are realised continually from exploration galleries. When inclined jet-grouting method is used, the securing of driving of mining works is carried out from the surface in a continuous way, which can provide for securing the whole perimeter of a gallery. However, this way of securing can only be used if there is an optimal overburden and surface accessibility in the service area; i. e. the arrangement of underground services as well as the development must enable for the realisation of driving works in terms of disposition. If the service area is inconvenient in this respect, the securing can still be carried out with upward jet-grouting realised from driven galleries in a step-by-step way enabling subsequent drilling steps. This is a way to secure an overburden, as well as partly the side walls of driven galleries. Sanitation jet grouting is projected in non-cohesive soils and uses cement or clay-cement grout mixtures.

When inclined jet-grouting method is used, the securing of driving of mining works is carried out from the surface in a continuous way, which can provide for securing the whole perimeter of a gallery. However, this way of securing can only be used if there is an optimal overburden and surface accessibility in the service area; i. e. the arrangement of underground services as well as the development must enable for the realisation of driving works in terms of disposition. If the service area is inconvenient in this respect, the securing can still be carried out with upward jet-grouting realised from driven galleries in a step-by-step way enabling subsequent drilling steps. This is a way to secure an overburden, as well as partly the side walls of driven galleries. Sanitation jet grouting is projected in non-cohesive soils and uses cement or clay-cement grout mixtures.

Reinforcement micropile umbrellas

Reinforcement micropile umbrellas

These are commonly designed from micropiles í 108/16,114/10 or í 70/12 mm, and are used for securing the overburden stability in the course of breaking of mining works; they are also utilised for passages of underground works under overburden that requires minimalised subsidence. Micropile holes are usually designed in a horizontal way, or they pursue the profile of a driven gallery and they are mainly used in cohesive soils, semi-rock and rock massifs. It is possible to use micropiles grouted at full length with the help of individual levels, or micropiles set only into a cement grout. Grouting is usually carried out with the use of a cement grout mixture. Micropile umbrellas are mostly carried out from entrance shafts or mining work portals and from a tunnel face during driving.

Collector connections for underground services

These are drilled connections mostly of í 100 to 300 mm profiles for individual underground services that connect a service collector with single media consumers. Their drilling and completion are carried out from the main galleries of a driven collector, or from driven connection galleries in houses leading into the main galleries. Holes for these connections are usually an upward type and their length can reach up to 20m.

Casing of entrance and technological shafts Shafts in underground works serve for the entry and transport of individual media as well as the building material. They can especially be cased with the use of the following technologies of special foundation: diaphragm monolithic reinforced concrete walls; secant pile walls; jet-grouting; drilled or rammedriders and micropiles. These structures are normally an chored either with strand anchors or they are strutted with steel spacing frames. The principles of realisation of these technologies are described in the previous chapters.

Shafts in underground works serve for the entry and transport of individual media as well as the building material. They can especially be cased with the use of the following technologies of special foundation: diaphragm monolithic reinforced concrete walls; secant pile walls; jet-grouting; drilled or rammedriders and micropiles. These structures are normally an chored either with strand anchors or they are strutted with steel spacing frames. The principles of realisation of these technologies are described in the previous chapters.

Securing the existing development in the course of realisation of underground works

To secure the stability of the existing development in the subsidence area within the process of construction of underground structures requires in some cases to underpin the foundation structures of existing buildings with the help of jet grouted columns or micropiles. These structures are designed in the way that the load bearing upon the foundation is transferred deeper into the subsoil, which is not affected by driving of the underground structure, or in the way that subvertical curtain comes into existence. The curtain decreases influence of subsidence area and thus protects the buildings.